Selecting the right lithium battery dry room provider for your facility is a critical decision that can have a significant impact on the efficiency, safety, and overall success of your battery production or research operations. Lithium battery dry rooms are specialized environments designed to maintain extremely low humidity levels, which are essential for producing high-quality lithium-ion cells. Choosing the right partner involves evaluating multiple factors, from technical expertise to compliance with industry standards. This guide will walk you through the key considerations when selecting a lithium battery dry room provider.

Understanding Lithium Battery Dry Rooms

A lithium battery dry room is an environmentally controlled space that maintains ultra-low humidity levels, often below 1% relative humidity. These dry rooms are essential in the production and handling of lithium-ion batteries because moisture can lead to defects, reduced battery life, and safety risks such as short circuits or thermal runaway. Lithium battery dry room providers specialize in designing, constructing, and maintaining these environments to meet stringent specifications.

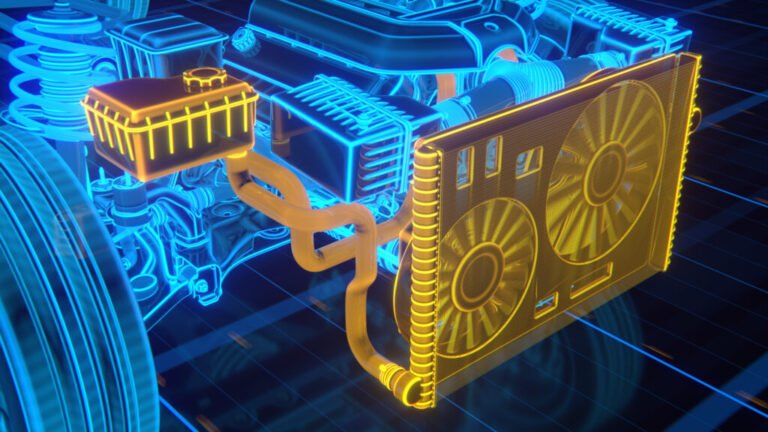

The core components of a dry room include advanced HVAC systems, dehumidification units, air filtration systems, and monitoring equipment. Each component must work in harmony to maintain precise environmental conditions, ensuring that the batteries produced are reliable and safe. Partnering with experienced lithium battery dry room providers ensures that your facility meets these critical requirements.

Key Factors to Consider When Choosing a Provider

Industry Experience and Expertise

One of the most important factors in selecting a lithium battery dry room provider is their experience in the battery manufacturing industry. Providers with a proven track record understand the specific challenges of controlling humidity in lithium battery production. They can offer tailored solutions that address your facility’s unique needs, whether you are setting up a pilot line or a full-scale manufacturing operation.

Experienced providers also stay updated on the latest technological advancements and industry standards. This ensures that your dry room incorporates cutting-edge design features that improve efficiency, reduce energy consumption, and enhance safety.

Compliance with Safety and Quality Standards

Safety is paramount in lithium battery production, and your dry room must comply with international safety and quality standards. Reputable lithium battery dry room providers are familiar with standards such as ISO 14644 for cleanroom environments and IEC 62619 for battery safety. Compliance with these standards ensures that your facility minimizes risks associated with moisture, contamination, and fire hazards.

Additionally, providers should offer documentation and validation processes to prove that the dry room meets the required specifications. This transparency is critical for regulatory approval and quality assurance in your manufacturing operations.

Customization and Scalability

Every lithium battery production facility has unique requirements, and a one-size-fits-all approach rarely works. Leading lithium battery dry room providers offer customizable solutions that can be tailored to your specific production capacity, layout, and operational goals.

Customization may include modular designs that allow for future expansion, flexible air handling systems to accommodate different battery chemistries, and specialized monitoring tools to track humidity and temperature levels in real time. Choosing a provider that offers scalable solutions ensures that your investment will remain viable as your facility grows.

Technology and Innovation

The technology behind lithium battery dry rooms is continually evolving. The best providers leverage innovative solutions such as advanced dehumidification systems, real-time environmental monitoring, and energy-efficient climate control. These technologies not only maintain optimal conditions but also reduce operational costs over time.

Innovative providers may also offer automation features, integrating sensors and data analytics to monitor conditions and predict maintenance needs. This proactive approach reduces downtime and helps maintain consistent production quality.

After-Sales Support and Maintenance

A lithium battery dry room is a complex system that requires regular maintenance and calibration. Choosing a provider that offers comprehensive after-sales support is essential to ensure long-term performance.

Reliable providers offer maintenance contracts, training for your staff, and rapid response services in case of system failures. Regular inspections and servicing of HVAC and dehumidification units help prevent equipment malfunctions, protecting your facility from costly production interruptions.

Questions to Ask Potential Providers

When evaluating lithium battery dry room providers, it is important to ask the right questions to gauge their capabilities and reliability:

- How much experience do you have designing and installing dry rooms for lithium battery production?

- Can you provide references from previous clients in the battery industry?

- Do your designs comply with ISO 14644 and IEC 62619 standards?

- How customizable are your dry room solutions, and can they be scaled for future expansion?

- What technologies do you use for dehumidification, air filtration, and environmental monitoring?

- What after-sales support, maintenance services, and training programs do you offer?

Asking these questions helps you identify providers who are not only technically competent but also committed to long-term support and customer satisfaction.

Evaluating Cost vs. Value

While cost is always a consideration, it should not be the sole deciding factor. The cheapest provider may compromise on quality, safety, or reliability, which can lead to higher long-term costs. Instead, evaluate the overall value offered by each provider, including design quality, technology, compliance, and after-sales support.

Investing in a high-quality dry room from a reputable provider ensures that your lithium battery production maintains high yield, consistent quality, and operational safety. Consider the total cost of ownership, including installation, maintenance, and energy efficiency, when making your decision.

Conclusion

Choosing the right lithium battery dry room provider for your facility is a strategic decision that affects safety, quality, and operational efficiency. By considering factors such as industry experience, compliance with standards, customization options, technological innovation, and after-sales support, you can select a provider that aligns with your facility’s goals.

Engaging with a reputable lithium battery dry room provider ensures that your production environment is optimized for moisture-sensitive lithium-ion batteries, safeguarding both your investment and your brand’s reputation. Careful evaluation and thoughtful decision-making will lead to a facility that operates efficiently, safely, and reliably for years to come.